Day-184-Rebuild-1

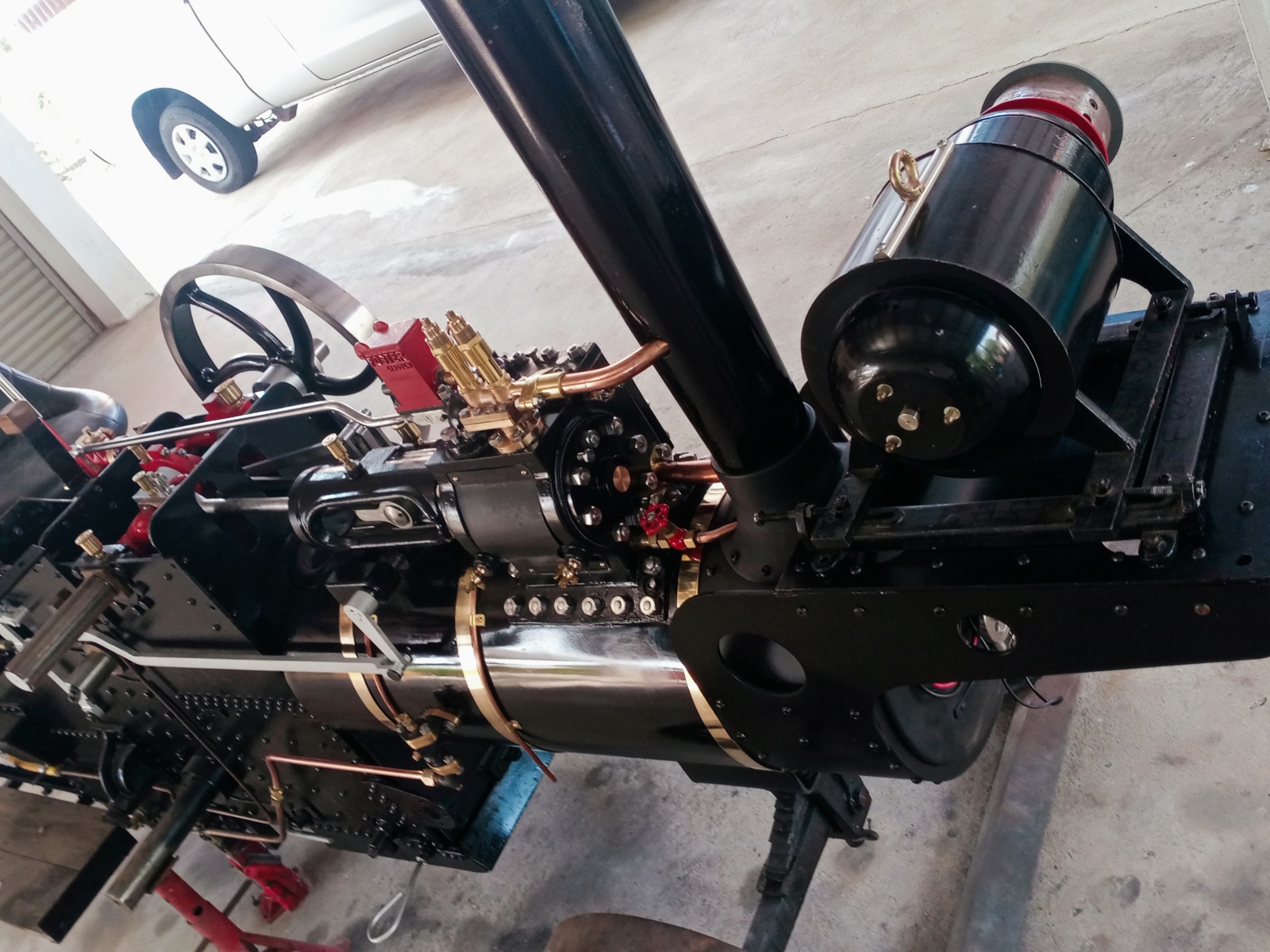

It’s been 184 days exactly – 6 months – from start of stripdown to the rebuilding status as you see on this page.

NOTE: Click on an image to see a full-screen view. Esc to return.

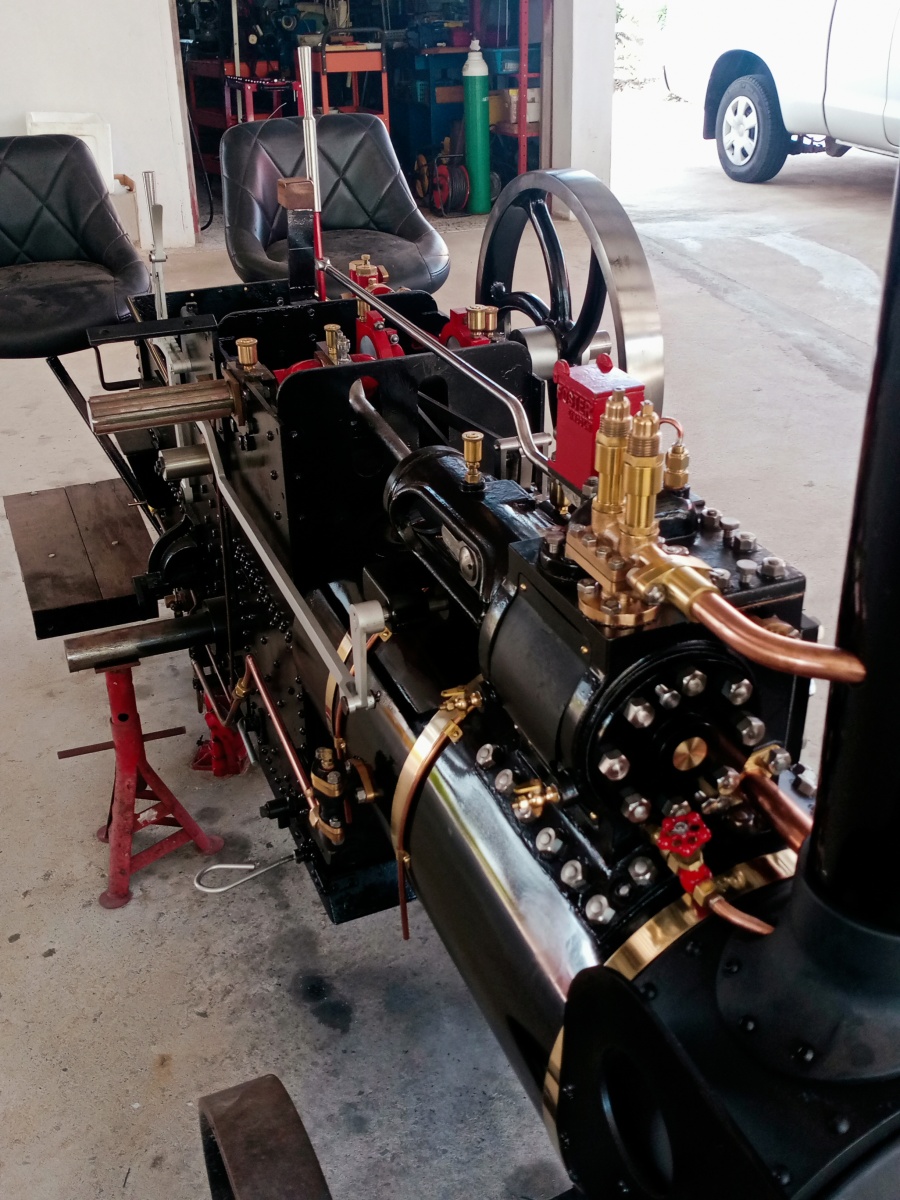

Gallery 01 General Views

NOTES:

- Every part shown here (except front axle & wheels) has been cleaned and painted/polished.

- The Reversing Lever, Quadrant, Reach Rod, Lifting Arm are all painted.

- All handles are stainless steel.

- Note the black painted Boiler Clack Valves.

- All paint is rated for 400F (230C) or over.

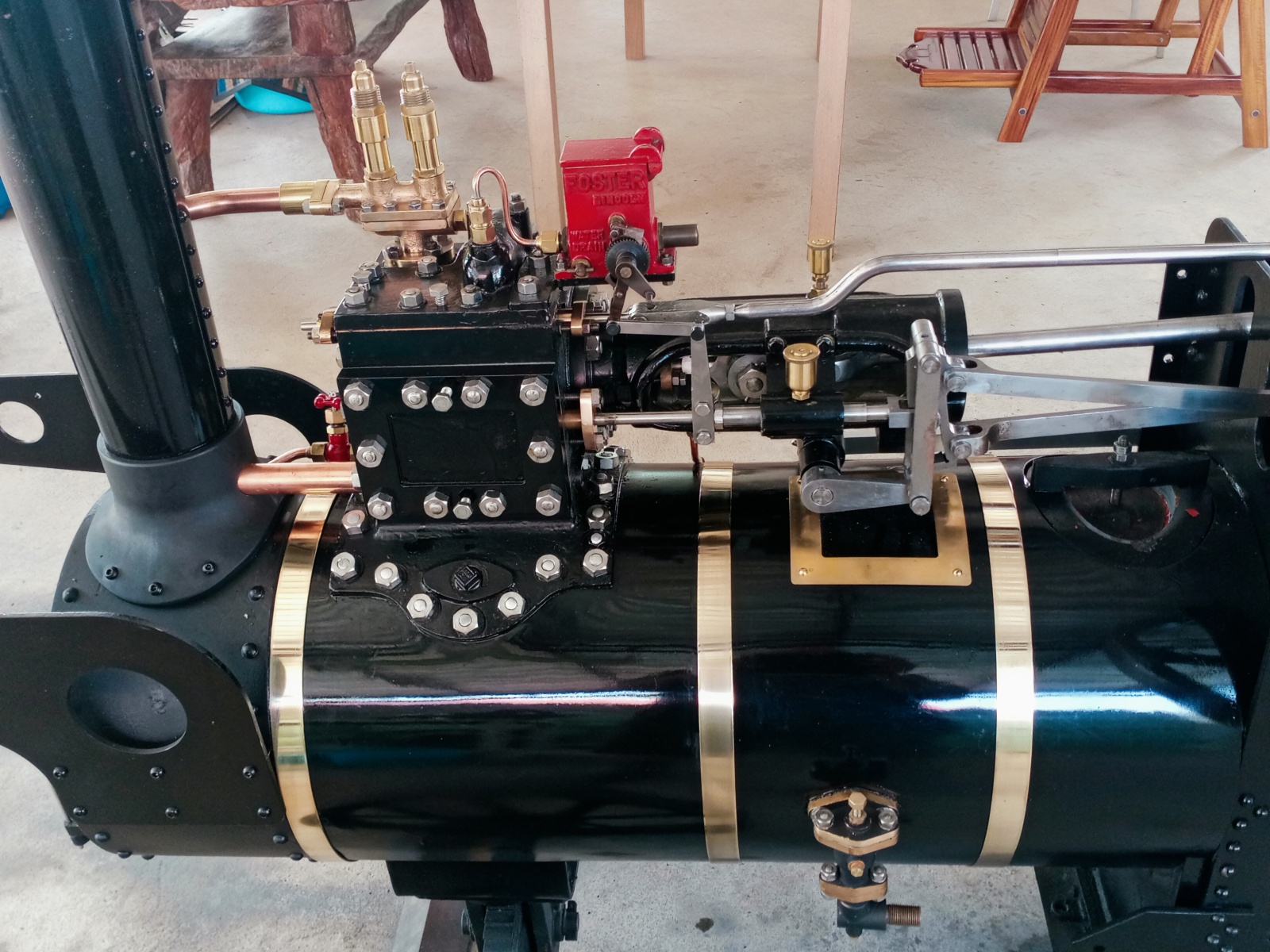

Gallery 02 Cylinder-LHS

NOTES:

- All nuts are hand-made to scale (19050 and stainless steel.

- Notice the oil drip-tray let into the boiler cladding.

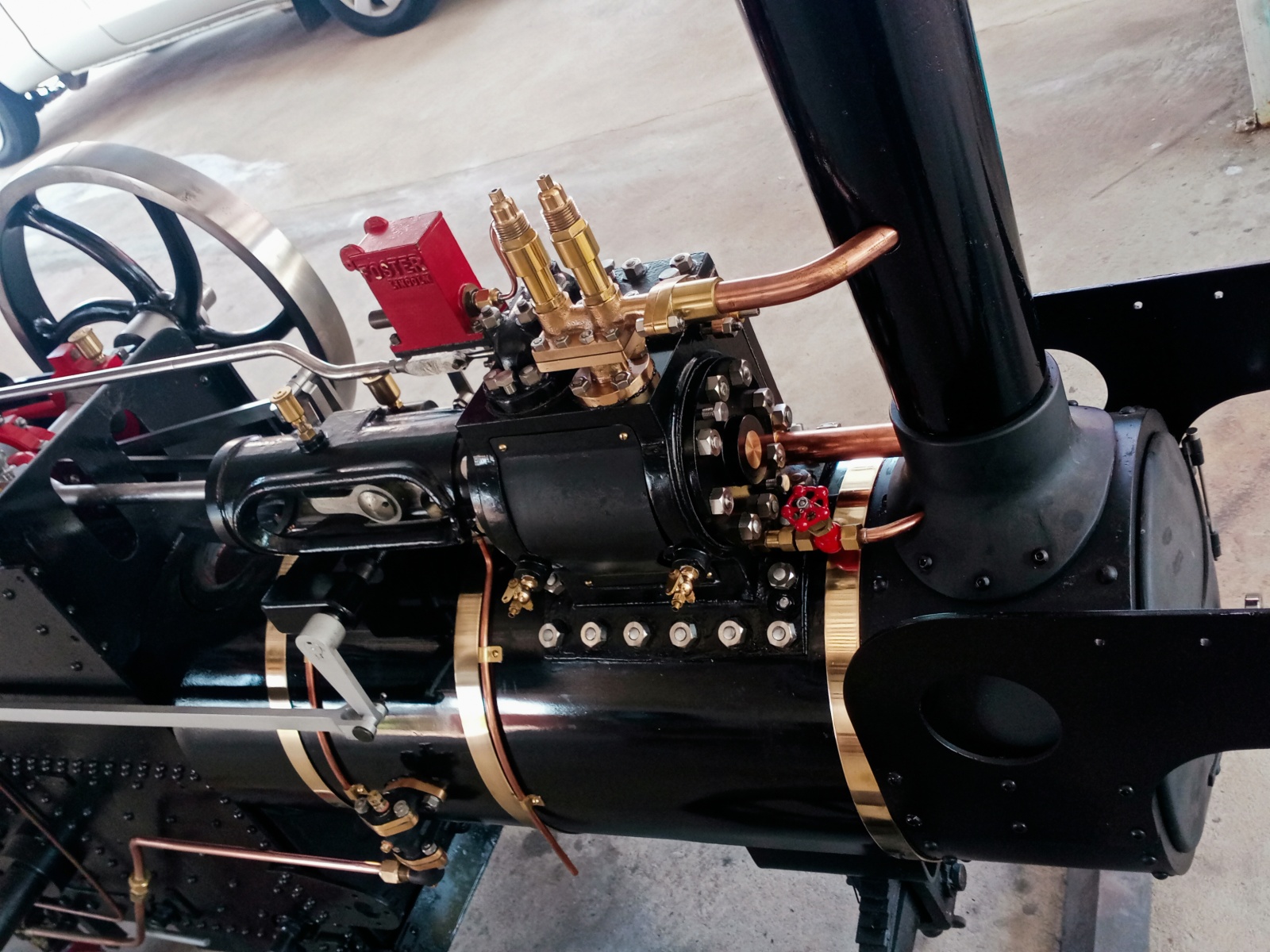

Gallery 03 Cylinder-RHS

NOTES:

- All covers have stainless steel M8 forcing screws to aid removal.

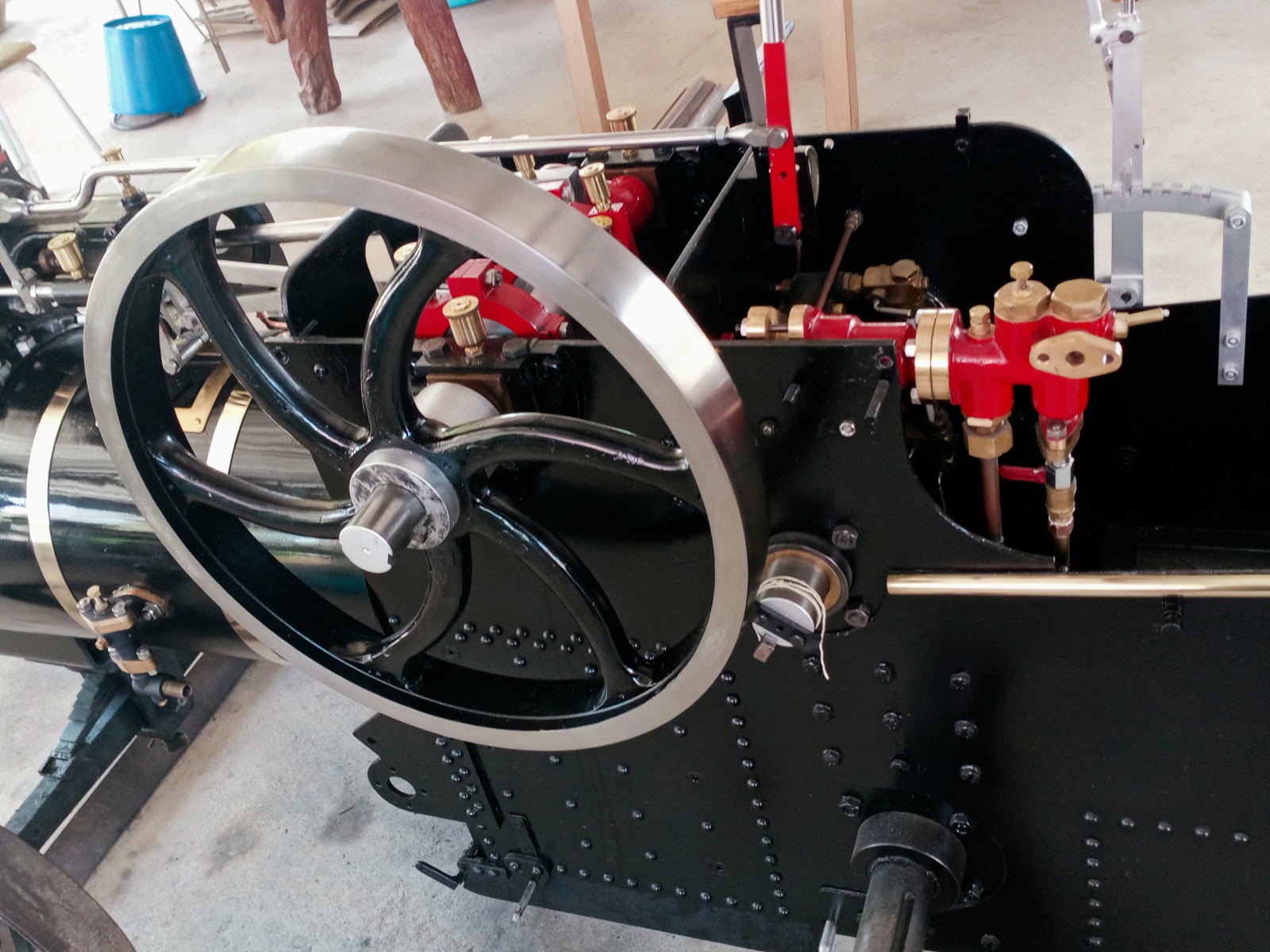

Gallery 04 Crankshaft

NOTES:

- Connecting Rod and Valve Rods are protected with Vaseline.

- Non-bearing surfaces of Crankshaft are painted.

- Some Oilers to be upgraded.

- Bearing Keep Plate Nuts to be wired.

Gallery 05 Dynamo

NOTES:

- Bearing surface of Dynamo Pully to be cleaned.

- Dynamo itself and accessories not completely installed yet.

Gallery 06 Blower Valve

NOTES:

- Note the split pin securing the handwheel.

Yes, George, Vaseline does look better than normal grease and as you say it’s easier to remove. Not forgetting that using Vaseline was your suggestion in the first place so thank you George.

It does take up oceans of time to make posts on the website, which is why they are few and far between. I do enjoy updating the website and adding content but whilst doing so I’m always itching to get back out into the workshop and get on with working on the engine(s).

This is particularly so when I need to make a Youtube movie which can take days – quite literally.

not only have you spent a lot of time and effort on the engine. But a lot of work on the Web site content.

Good to see the vaseline in use. I use it on all the bright steel. as it looks better than the normal dark grease.