Making And Fitting Cast Rubber Block Strakes To Traction Engine Wheels

In the previous page Traction Engine Rubber Tyres I introduced the need for rubber tyres on traction engines and gave some background and history.

I explained how my investigations into obtaining tradditional rubberised wheels had led me to investigate fitting rubber block strakes instead, culminating in opting for cast rubber block strakes.

This article is all about designing, sourcing and fixing cast rubber block strakes.

From the previous article you will recall that I was in my friendly local machine shop where Mr Teera had looked at my drawings for the built-up rubber block strakes and they were discounted because of the impossibility of cutting thick sheet rubber.

Instead Mr Teera suggested casting the blocks in a mould and he showed me some blocks he had made for other customers. Typically they were to be used as anti-vibration mounts under machinery similar to this:-

Mr Teera said that the main cost would be in making the mould and that the cost of casting the individual blocks was miniscule in comparison.

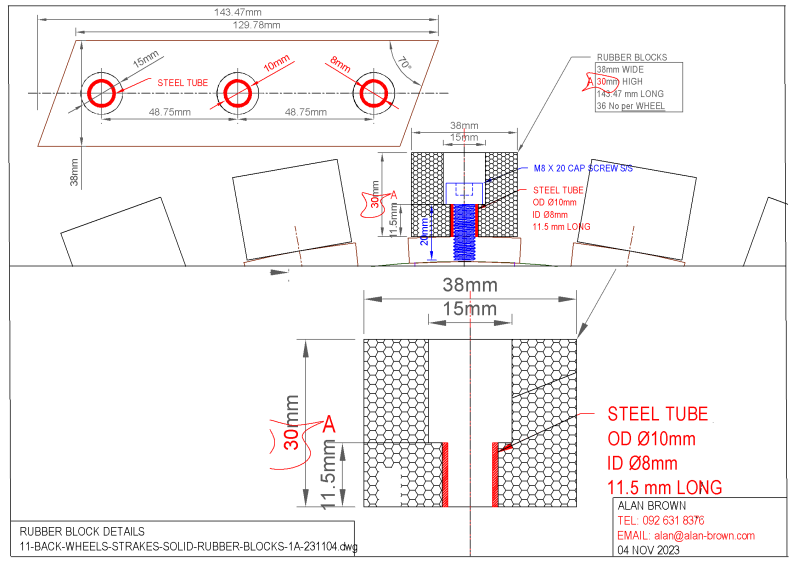

So I agreed to let Mr Teera make the mould and I amended my drawings to suit as below. I also make a sample cast rubber block strake (from wood!) with the agreed steel tube inserts. All as detailed below.

In addition to the apparent simplicity of making these cast solid rubber block strakes there is the advantage that steel tubes can be included solidly bonded to the rubber. Thus the cap srew will abut against the end of the steel tube instead of compressing the rubber.

I also increased the cap screw size from M6 to M8 and the thickness of the rubber from 25 mm to 30mm.

This rubber depth of 30mm may still prove to wear out quickly but

a) I don’t actually drive the engine that much compared to other owners, and

b) the strakes can readily be replaced if necessary.

My friend’s 6″ Little Samson Traction Engine has conventional rubber tyres 40mm thick.

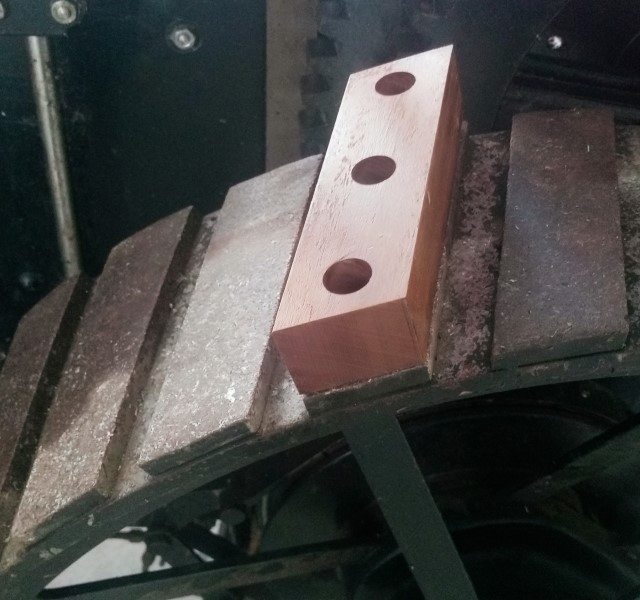

Here are some photos of the (wooden) cast solid rubber block strakes sample:-

So Mr Teera has the drawings and sample cast rubber block strake.

He said the mould would be finished next week,

Let’s see what happens.

But wait, there’s more…

Cast Your Own Solid Rubber Block Strakes

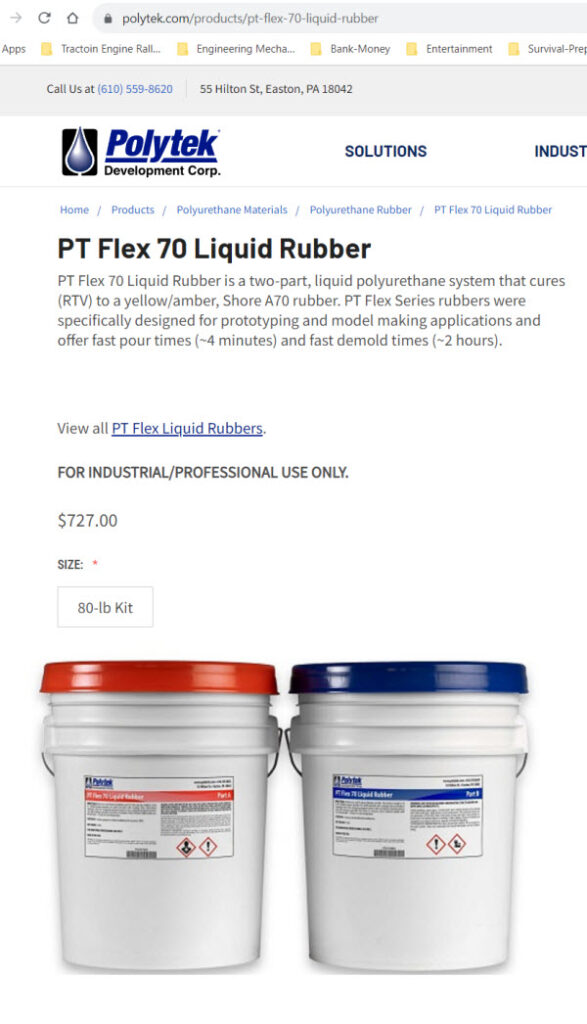

Reflecting upon the story so far it ocurred to me that it should be easy to cast your own solid rubber block strakes using a simple mould and a pourable liquid rubber, soemthing like this:-

Note the fast demould time of ~ 2 hours and high Shore strength of A70 – near the top of the scale.

Please note that I am not suggesting that this material is suitable – it’s the wrong colour for one thing – but it’s an indication of the type of products available.

Something to persue if Teera doesn’t come up with the goods.

Please comment below.

Thank you.

Hi paul

Id say your spot on about the strakes I done a job on a 4” Burrell last year it had rubber strakes glued on to steel strakes they were about 20 mm high and no way you could stay on it going across the concrete yard here on the grass a little better but you felt every strake hitting the ground

Alan,

Not wanting to cast doubt on your plan but I think you may find the engine will still run quite rough. Because the angle of the strakes is so shallow you will still feel the transition from one block to the next on the road surface, even on a good smooth road. Dave has quad track on the Avelling and the angle of that is a bit sharper but we still get a harmonic “bounce” on the engine in big wheel. It is quite uncomfortable on a long run you are constantly “vibrated” up and down, after about 3 miles you are happy to be getting off!

Have you got in mind a hardness for the rubber? Soft is better for ride but not good for longevity. For a smooth ride you can’t beat a continuous band.

Best regards,

Paul.