Traction Engine Rubber Tyres – How To

This and follow-on articles show how to get rubber tyres fittend to you Little Samson Traction Engine or any other traction engine. My experience in getting my steel straked traction engine wheels rubberised is presented in full detail.

Why You Need Rubber Tyres

The roads where I normally run the 6″ Little Samson Traction Engine are pretty rough country lanes, full of potholes and attempt to repair them which only makes the going rougher!

Almost every run, due to the vibration, something comes loose. As I say about fasteners “If it isn’t locknutted, loctited, split-pinned or wired it will come loose”.

On one run I noticed that the hornplate set screws had come loose and the hornplates were wobbling about! This also happened to a friend of mine, a fellow Little Samson Traction Engine builder, who had the same issue. I fixed my hormplates by changing the type of setscrew and applying loctite and my friend just used loctite but he also tack welded the hornplates to the firebox!

On another occasion the screws holding the back plate and feed pump came loose. etc, etc.

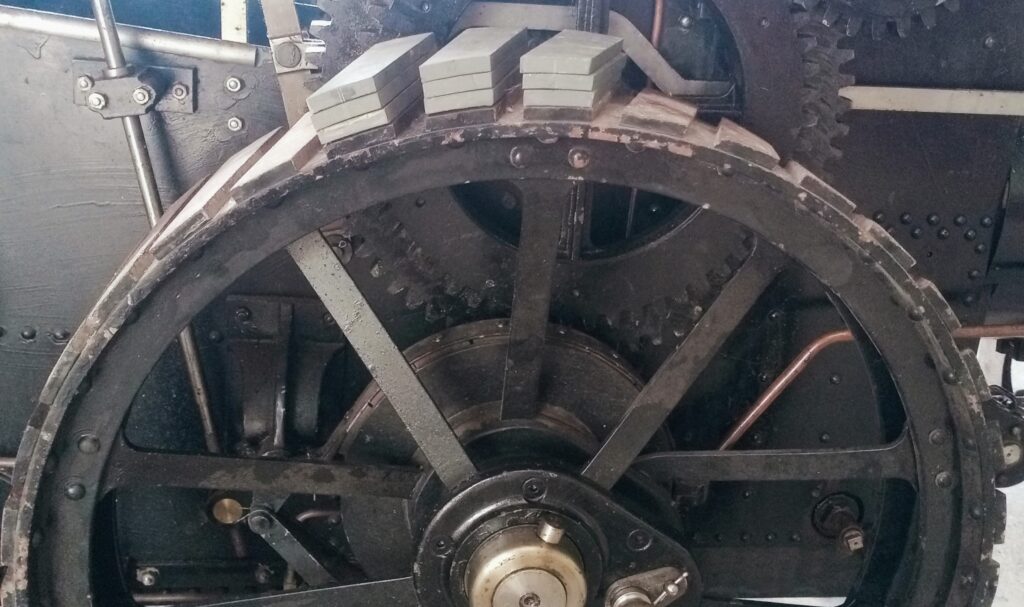

I therefore decided it was a ‘must’ to get my traction engine wheels (at least the rear, straked steel wheels) rubberised. This is how I faired.

P.S. Here I’m referring to ruberising the back wheels of my Little Samson Traction Engine which are steel strakes on steel rims. The front wheels are steel but have smooth steel bands so there is comparatively little vibration cause by those and I’ll deal with those wheels later if I have to.

Tradditional Rubber-Tyred Traction Engine Wheels

Of course, you already know what these are, but for completeness here’s a brief summary:-

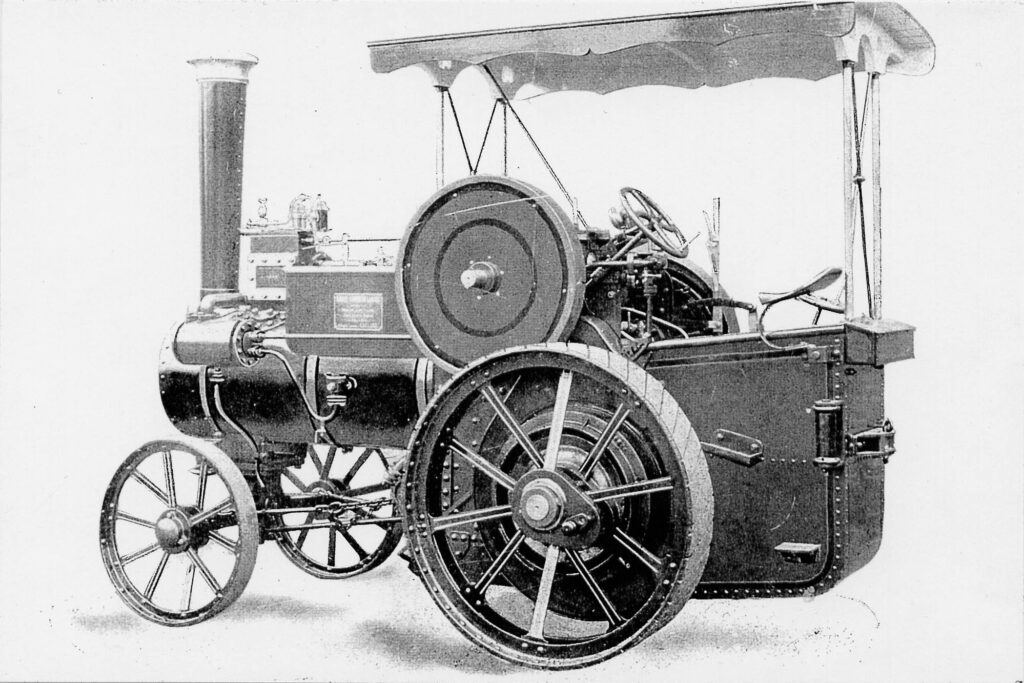

According to an article by Farmers Weekly, steel wheels with steel strakes were standard equipment on steam traction engines in the 1800s and early 1900s but as road surfaces improved solid rubber tyres became first fitted as standard in the factory in the 1920s.

Below are some photos of steel straked wheels and rubber tyred wheels on real full-sized Little Samson Traction Engines.

The rubber wheels seen in the last picture above are commonly used on traction engines, miniature and full sized, today. They look to be bonded directly to cast-iron wheels without steel strakes. Let’s call them ‘normal’ rubberised wheels.

Getting Traction Engine Wheels Rubberised In The U.K.

There are several organisations in the U.K. today offering to rubberise the wheel of traction engines for their owners and/or builders, the main ones being Clifton, Leakes and Reliant.

I have seen prices to have the wheels of a 6″ Little Samson Traction Engine quotes as between £1.5k and £2k. Not sure if that was for all four wheels or just the back wheels. Also I have seen a price of £3k for an 8″ Little Samson Traction Engine for all four wheels – but that translated into an actual 4,800 EUR – £4,164.46 at current exchange rates.

Please be aware that prices differ from supplier to supplier and also upon the service offered of which there are may variations:-

- Rubber directly to steel wheels either straked or non straked.

- Rubber onto steel bands pressed onto the steel wheels (which could be straked or non straked).

- Shotblasting and priming of wheels.

- Format of rubber, thick, thin, plain, grooved or profiled.

- Delivery back to the customer.

- And so on.

My Attempt To Get My 6″ Scale Little Samson Traction Engine Wheels On Rubber Tyres

My first attempt at getting rubber tyres on my traction engine wheels was to see if I could get the ‘normal’ tyres fitted in the U.K.

I sent an enquiry by email to BH Leak & Son as below, using the email address on their website:-

|

EMail to: xxx @ bhleakerubber.co.uk Attached:- |

I didn’t get a reply to the email and wondered if I should have sent the enquiry using the Form on their website. Anyway, I don’t live in the U.K., I live a third of the way round the world from there so any U.K. quoted price I would have to double to allow for shipping and import duty.

So I gave up on this option.

Too late now anyway, things have moved on since then.

By the way, please don’t take my experince as an indication of Leak’s performance. Some people praise them highly.

Rubber Block Wheels

Inspired by an email from a friend of mine, a fellow Little Samson Traction Engine builder, I started to look into rubber block wheels. By this I mean thick rubber strakes bolted to the existing steel strakes.

At first I investigated machined solid rubber blocks then built-up blocks and then went back to cast solid rubber blocks.

Machined Solid Rubber Blocks

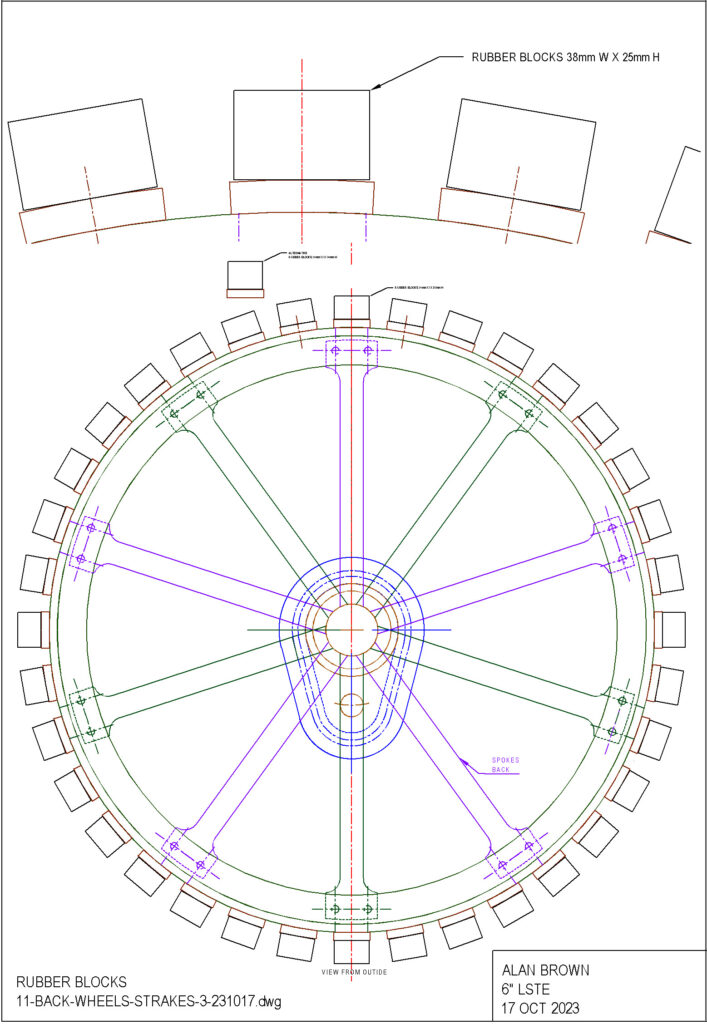

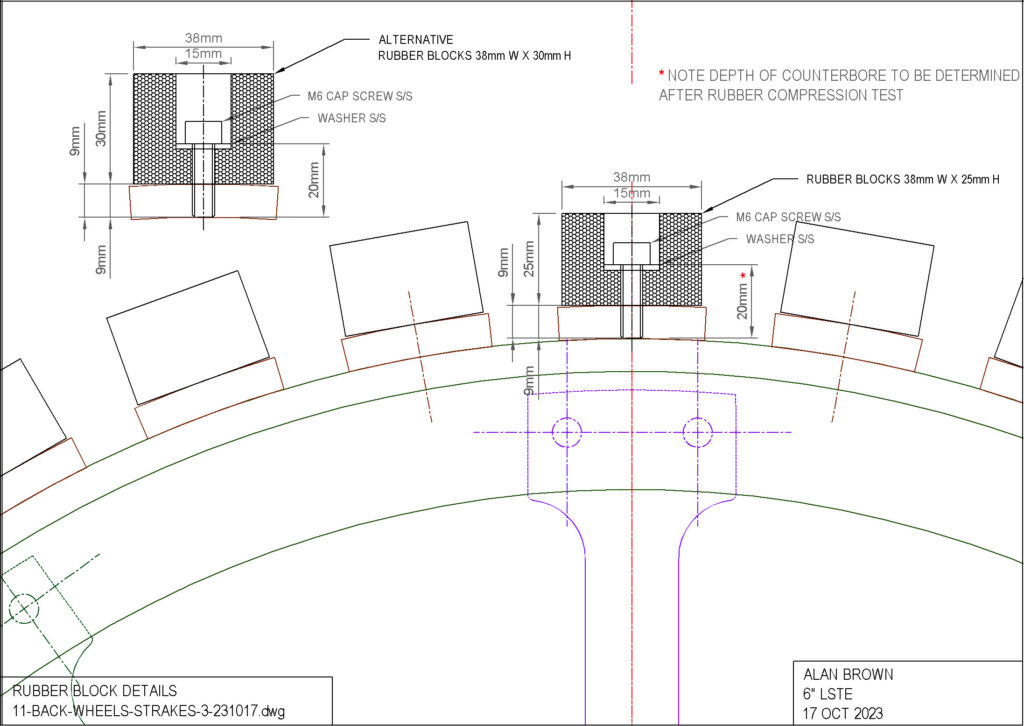

I found online a source of solid rubber block approximately the size I needed to make the rubber block strakes. I’ll show that source below but first let’s look at what I’m talking about. Here is a mock-up and some drawings I made:-

Practical Questions Arising

1) Fix to the strakes using cap screws from the rubber side. Drill through strakes and use nuts or tap the strakes?

2) Probably ‘drill’ the blocks using a toothless tubular pipe with sharp end.

3) But how to create a flat bottomed counterbore for the cap screw heads?

Here are some details of the source of rubber blocks and the costs:-

Rubber Block Supplier And Costs

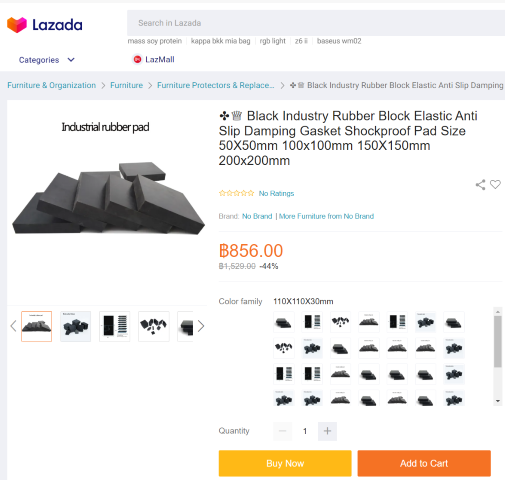

The supplier is a company in China advertising on a well known shoppping website called Lazada.

Seems all blocks are priced at 856 Baht (22 EUR) each. (Free shipping)

Most economic would be 110X110X30 (If 30mm high chosen) Can be cut to make 3 strakes – but a bit on the small side.

36 strakes per wheel. So 36/3 = 12 blocks per wheel.

12 blocks X 22 EUR X 2 wheels = 528 EUR.

Sounds reasonable. Better than £2k from Leakes – or £3k+ landed in Thailand.

(Note: To add cap screws and washers. When I first saw these a few weeks ago they were priced at 387 Baht. i.e. the price has more than doubled!)

Drilling The Counterbore

I questioned above how I would drill the counterbore for the cap screw. After much research online I came to the conclusion that this would be impossible for me.

So this machined solid rubber block idea was abandoned and time to think again.

Built-Up Rubber Block Strakes

I came up with the idea of using two layers of rubber glued together at the line of the bottom of the coutebore.

There seemed to be plenty of glue availabe strong enough for the job. In fact it seemed that normal spuperglue was the best glue to use for rubber.

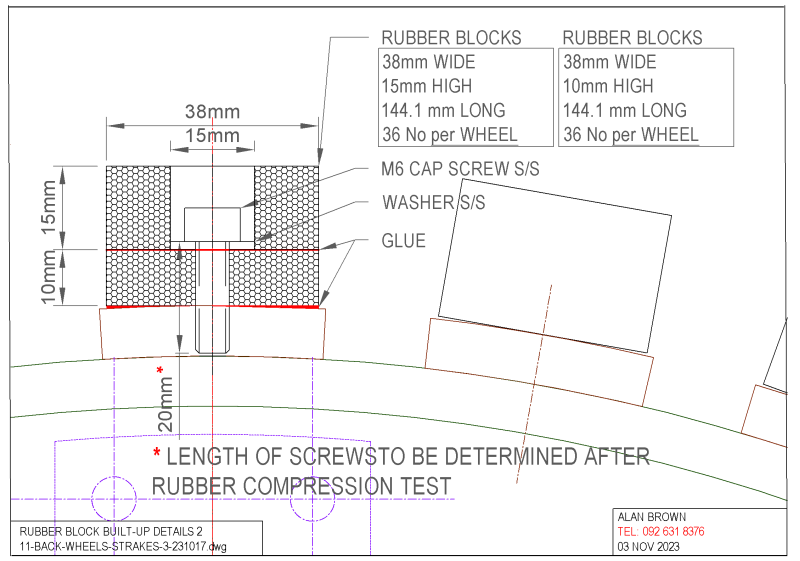

So I modified my drawings accordingly as follows:-

Although I thought this idea might work, I was a bit concerned as to how I would cut the rubber blocks to size. I was thinking to use the vertical bandsaw.

Also I was reluctant to buy from China when rubber was made here in the country where I was living.

So I went to my local and friendly machine shop, Teera, with my drawings to see if they could help.

The first thing he said was that he couldn’t cut 15mm rubber not even on his 20T guillotine! He showed me a piece of 1omm rubber sheet that he had cut but the edges were rough and that was the limit.

Then he made a suggestion. Cast rubber block strakes.

Cast Rubber Block Strakes

Well, at this stage I thing this post is long enough. The story continues on the next post called Cast Rubber Block Strakes.