Fabrication Of The Traction Engine Boiler And Insurance Certification Is Now Complete

4th November 2014 – A Milestone Day In The Little Samson Traction Engine Build Programme

A couple of days ago I received the email below from Tony Baldwin (AJB Engineering (Ripley) Limited):-

| Hi Alan Your boiler is now tested and ready to be collected. Regards Tony |

Well I can tell you I was really excited by this news, I have waited nearly six months since placing the order for the boiler. This is actually better news than I expected because the quoted delivery date was ‘up to nine months’.

Photographs of My 6 Inch Scale Little Samson Traction Engine Boiler

I had already visited Tony in his workshop at Ripley, Derbyshire, just after I placed the order for my boiler and posted some Photos Of 6″ Scale Little Samson Traction Engine Boilers (Plus Others) Under Construction on the ModelEngineeringInThailand.com website.

But these photos, although they look like the other photos, are different because they are photo’s of my Little Samson Traction Engine Boiler. This is the first glimpse I have had of my boiler.

Most of the photos were taken some time ago during construction and there is only one of the finished boiler. To me this makes the photos more interesting – good to see what goes into making a steel boiler for a half-sized traction engine!

Photo 1: Boiler Back Plates

Left to right are (I think) the firebox tube plate, boiler backhead and firebox backhead all cut out of steel plate ready for welding into the boiler.

It looks to me like there are two sets of boiler backplates here!

When you look at the other photos below you’ll probably get the same impression that I do – these are photos of two identical boilers being constructed together. Nothing wrong with that – if Tony can get enough orders for the same kind of boiler and batch-build them it helps to keep the price down.

Anyway a comment on the above photos – look at those beautifully clean and big countersinks. I wish I knew what countersinking tool Tony used.

Another point – notice how thick the plates are. According to the Little Samson construction drawings they should be 12, 10 and 8 mm thick.

Photo 2: Smokebox Tubeplate And Inner Firebox Wrapper

Note the massive chamfer on the front tubeplate ready for fillet welding into the boiler shell, the tubeplate being 12 mm thick and the boiler shell being 3/8″ (10 mm) thick.

Looking at the bottom inner firebox wrapper (the one on the floor) it looks like it has been fabricated from two pieces with a butt weld. This method of fabrication isn’t shown on the construction drawings.

Photo 3: Firebox And Boiler Barrel

The six largest countersunk holes are to take 1″ diameter stays that will be drilled and tapped M8 for the bolt fixings through the hornplates. The surface of the boiler barrel looks a bit rough.

Photo 4: Boiler Complete

A good view of the foundation ring and the inside of the firebox. Top-right you can just about make out a boiler washout bush. The hole for it can be seen on the side of the outer wrapper (top left) of the photo above.

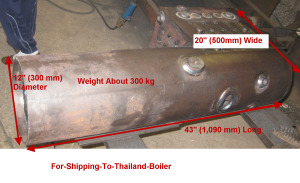

Photo 5: Dimensions Of A 6 Inch Little Samson Boilers

Overall dimensions of a Little Samson traction engine boiler in 6 inch (half size) scale. (Note this is not a Little Samson boiler – just the dimensions are those of a Little Samson boiler drawn on another boiler of similar style.)

I marked this photo up to send to shippers to get quotes for shipping the boiler to Thailand.

How To Ship A Half Sized Steam Traction Engine Boiler to Thailand

And shipping the boiler to Thailand is turning out to be another of those long drawn out episodes of mystery, misinformation and grief that I have come to expect when dealing with anything in Thailand.

So shipping the boiler to Thailand (if it ever gets shipped) is the subject for another web page.

It’s truly enjoyable looking at good craftsmanship…and your fabricator certainly knows his trade.